What Is the Symbol for Full Penetration Weld in Drawings?

The symbol for a full penetration weld, essential in guaranteeing maximum weld strength and structural integrity, consists of a reference line, an arrow, a tail, and a filled-in triangle indicating weld requirements and details. This symbol guarantees complete fusion across material thickness, eliminating voids and providing superior mechanical performance.

Frequently used in structural engineering, pressure vessel fabrication, and pipeline construction, full penetration welds offer enhanced durability and load-bearing capacity. Understanding these symbols is vital for correct weld application and compliance with industry standards.

Discover the necessary design elements and benefits associated with full penetration welds to elevate your welding quality.

Key Takeaways

- The full penetration weld symbol includes a reference line, arrow, tail, and a filled-in triangle.

- It ensures maximum strength and integrity by eliminating voids and incomplete fusion.

- The symbol is critical for load-bearing connections in structural engineering and pipeline construction.

- Non-destructive testing methods like visual inspections and dye penetrant testing ensure quality control.

- Compliance with standards such as AWS, ISO, and ASME is essential for weld quality and safety.

Definition and Importance

A full penetration weld, also known as a complete joint penetration (CJP) weld, is a weld where the filler material fully penetrates and fuses the entire thickness of the materials being joined. This type of weld guarantees maximum strength and integrity, making it vital in critical applications such as structural steelwork, pressure vessels, and pipelines.

Full penetration welds eliminate the potential for internal voids or incomplete fusion, enhancing the mechanical performance and durability of the joint. The thorough fusion achieved in CJP welds provides high resistance to fatigue and fracture, which is essential in safety-sensitive industries.

Understanding the definition and importance of full penetration welds is fundamental for engineers and welders to ensure adherence with stringent industry standards and specifications.

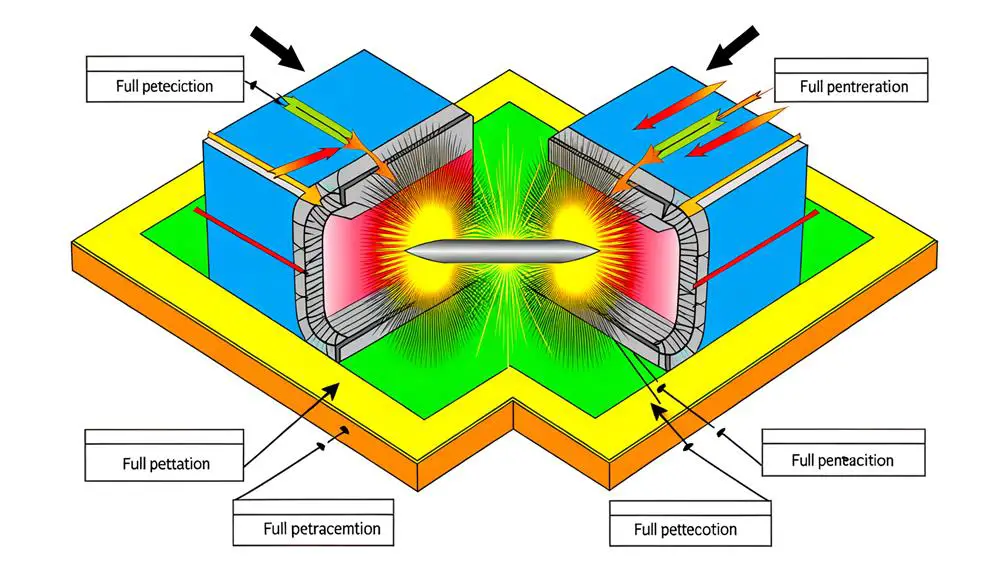

Symbol Design Elements

Understanding the symbol design elements for full penetration welds is crucial for accurately interpreting welding blueprints and guaranteeing compliance with industry standards.

The primary components of these symbols include the reference line, arrow, tail, and basic weld symbol.

The reference line serves as the foundation, indicating the location of the weld.

The arrow points to the joint area that necessitates welding.

The tail, if present, includes supplementary information such as welding process or other special instructions.

The basic weld symbol for full penetration typically features a single or double-sided arrow with a filled-in triangle, denoting complete joint penetration.

Mastery of these elements ensures precise communication and execution in welding projects, maintaining structural integrity and safety.

Reading the Symbol

Reading the symbol for a full penetration weld requires understanding its components, proper placement, and orientation in technical drawings.

Key elements include the reference line, arrow, and weld symbol, each conveying specific information about the weld.

Additionally, the tail of the symbol often contains critical details such as welding process, specifications, or other pertinent notes.

Components of Weld Symbol

Deciphering a weld symbol involves understanding its various components, including the reference line, arrow, and supplementary symbols, which collectively convey essential information about the weld type, size, and other specifications.

The reference line serves as the foundation of the weld symbol, providing a baseline for additional details.

The arrow connects the reference line to the joint location on the drawing, indicating where the weld is to be applied.

Supplementary symbols, such as contour symbols or finish symbols, offer further specifications, such as desired weld shape or surface finish.

These components must be read in conjunction with each other to fully understand the weld requirements, ensuring precise communication and execution in welding operations.

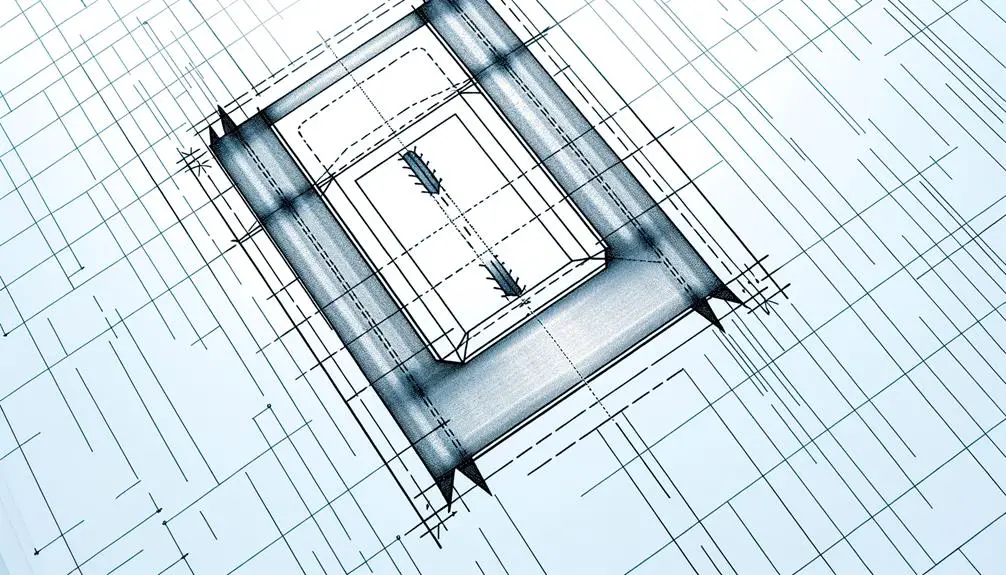

Placement and Orientation

Accurate interpretation of a weld symbol's placement and orientation is crucial for guaranteeing the correct application of the specified weld on the joint. The placement determines whether the weld should be performed on the arrow side, the other side, or both sides. Orientation of the symbol's arrow line and reference line defines the exact location of the weld.

| Symbol Feature | Description |

|---|---|

| Arrow Line | Points towards the joint location |

| Reference Line | Indicates the side for weld application |

| Arrow Side | Weld performed on the side the arrow indicates |

| Other Side | Weld performed on the opposite side of the arrow |

| Both Sides | Weld performed on both sides of the joint |

Correctly reading these aspects guarantees compliance with engineering specifications and structural integrity.

Interpreting Tail Information

Understanding the placement and orientation of weld symbols is complemented by accurately interpreting the tail information, which provides additional details such as weld process, specifications, and supplementary data necessary for executing the weld.

The tail of the weld symbol can include abbreviations for the welding process (e.g., SMAW for Shielded Metal Arc Welding), references to specific welding codes or standards, and any additional instructions, such as preheat requirements or post-weld heat treatments.

Proper interpretation of the tail information guarantees adherence to the required procedures and quality standards, impacting the structural integrity and performance of the weld.

Misreading or overlooking this critical information can lead to non-compliance with specifications and potential weld failures, undermining the overall project's success.

Common Applications

Full penetration welds are commonly employed in structural engineering, pressure vessel fabrication, and pipeline construction to guarantee maximum strength and integrity.

In structural engineering, these welds are essential for the connections in steel frameworks, ensuring load-bearing capacity and stability.

Pressure vessel fabrication relies on full penetration welds to withstand high internal pressures, preventing leakage and catastrophic failures.

Pipeline construction uses these welds to create robust joints capable of enduring the stresses of fluid transport and environmental conditions.

The consistency and reliability of full penetration welds make them indispensable in applications where safety and performance are paramount.

Their use is crucial in maintaining structural integrity and operational safety across various demanding industries.

Benefits of Full Penetration Welds

Full penetration welds offer significant advantages, such as enhanced structural integrity, superior load-carrying capacity, and a seamless joint appearance. These welds guarantee complete fusion of the base materials, which contributes to the overall durability and reliability of the structure.

Additionally, the smooth finish achieved with full penetration welds minimizes the need for extensive post-weld treatments.

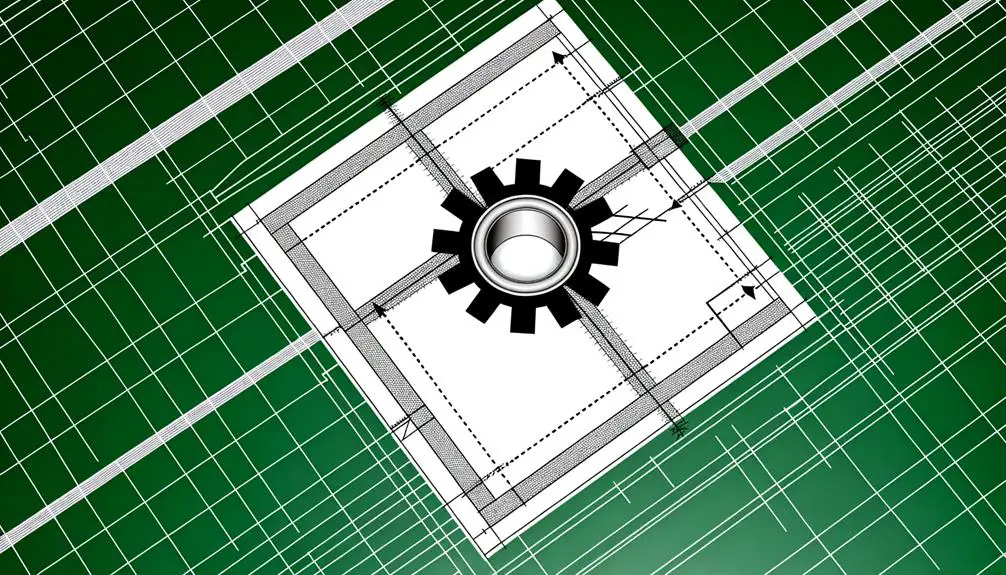

Structural Integrity Assurance

The implementation of full penetration welds greatly enhances structural integrity by ensuring complete fusion across the entire thickness of the welded materials. This guarantees the elimination of any potential voids or incomplete fusion zones, which can act as stress concentrators and lead to structural failures.

| Aspect | Description | Impact |

|---|---|---|

| Material Strength | Uniform stress distribution | Increased durability |

| Defect Reduction | Minimizes inclusions and porosity | Lower risk of failure |

| Load Bearing | Continuous load path | Enhanced performance |

| Inspection Ease | Simplified non-destructive testing methods | Reliable quality control |

Full penetration welds provide an uninterrupted load path, ensuring the welded structure can withstand operational stresses. Their application is critical in high-stakes industries, including aerospace, automotive, and construction, where the integrity of joints is paramount.

Enhanced Load Capacity

Consistently, full penetration welds greatly enhance load capacity by providing a robust and continuous load-bearing path across the entire welded joint. This approach guarantees that the weld metal fully penetrates the base materials, eliminating potential weak points that could compromise structural integrity under stress.

The even distribution of stress loads across the joint minimizes the likelihood of localized failure, increasing the overall durability and reliability of the structure. Full penetration welds are particularly advantageous in high-stress applications, such as in aerospace, automotive, and heavy machinery where maximum strength is essential.

Seamless Joint Appearance

Achieving a seamless joint appearance is one of the key aesthetic and functional benefits of full penetration welds. This type of welding guarantees complete fusion throughout the joint thickness, eliminating discontinuities and imperfections that could compromise both visual appeal and structural integrity.

Full penetration welds result in a uniform and flush surface, which is particularly advantageous in applications requiring high cosmetic standards, such as architectural metalwork and automotive body panels. Additionally, the seamless finish enhances corrosion resistance by removing crevices where moisture can accumulate. This leads to longer-lasting welds with reduced maintenance requirements.

Welding Standards and Codes

Adhering to welding standards and codes guarantees the integrity, quality, and safety of full penetration welds in various industrial applications. Key standards, such as those set by the American Welding Society (AWS), International Organization for Standardization (ISO), and American Society of Mechanical Engineers (ASME), provide detailed guidelines on weld design, execution, and inspection.

These standards specify criteria for joint preparation, welding procedures, materials, and acceptance criteria. Compliance ensures that welds meet strict mechanical and metallurgical properties, reducing the risk of failure under operational stresses. Proper documentation and qualification of welding procedures and personnel are also mandated to ensure consistency and reliability.

Following these codes is crucial for achieving top-notch weld performance and longevity, thereby safeguarding both structures and operators.

Differences From Partial Penetration

Full penetration welds guarantee complete fusion through the entire thickness of the materials. Unlike partial penetration welds which only fuse partially. This distinction impacts structural integrity. Full penetration welds generally offer superior strength and load-bearing capacity. Additionally, application suitability varies. Full penetration welds are preferred for critical structural components.

Weld Depth Variations

Weld depth variations greatly impact the structural integrity and performance of welded joints, distinguishing full penetration welds from partial penetration welds. Full penetration welds guarantee the weld metal extends through the entire thickness of the joint, providing maximum strength and load-bearing capacity.

In contrast, partial penetration welds only penetrate partway, which may suffice for less critical applications but offer reduced strength.

Key differences include:

- Full Fusion: Full penetration requires complete fusion, eliminating voids and ensuring joint uniformity.

- Load Distribution: Full penetration welds distribute loads more evenly across the joint, enhancing durability.

- Inspection Requirements: Full penetration welds often require more rigorous inspection methods, such as radiographic or ultrasonic testing, to verify integrity.

Understanding these differences is essential for selecting the appropriate weld type.

Structural Integrity Differences

The structural stability of full penetration welds far exceeds that of partial penetration welds due to their ability to achieve complete fusion across the joint thickness.

Full penetration welds guarantee that the entire cross-section of the joint contributes to load-bearing, resulting in superior mechanical properties and resistance to fatigue. This thorough fusion minimizes defects such as voids and inclusions, which can compromise the weld's strength.

In contrast, partial penetration welds, limited to shallower depths, often leave unfused sections that can act as stress concentrators, reducing the joint's overall performance.

As a result, full penetration welds are essential in applications demanding high structural reliability and durability, ensuring optimal load transfer and resistance to dynamic stresses.

Application Suitability Factors

Evaluating application suitability, full penetration welds are preferred for critical structural components requiring robust load-bearing capabilities and minimal vulnerability to defects. These welds guarantee complete fusion across the entire joint thickness, providing superior mechanical properties and structural integrity.

In contrast, partial penetration welds are limited to less critical applications due to their reduced load-bearing capacity and higher risk of defect occurrence. The key factors differentiating full penetration welds from partial penetration welds include:

- Load-Bearing Capacity: Full penetration welds support higher loads due to complete fusion.

- Defect Vulnerability: Lower defect rates in full penetration welds enhance reliability.

- Application Scope: Full penetration welds are essential for high-stress, safety-critical structures, whereas partial penetration welds are suitable for less demanding applications.

Inspection and Quality Control

Maintaining the integrity of a full penetration weld necessitates rigorous inspection and quality control measures to meet industry standards.

Non-destructive testing (NDT) methods such as ultrasonic testing (UT), radiographic testing (RT), and magnetic particle testing (MPT) are crucial for detecting subsurface discontinuities and guaranteeing weld quality.

Visual inspections and dye penetrant testing (DPT) are also utilized for surface flaw detection.

Adherence to American Welding Society (AWS) D1.1 and ISO 5817 standards ensures compliance with predefined acceptance criteria.

Keeping welder qualifications and procedure specifications (WPS) up-to-date contributes to consistent weld quality.

Quality control documentation, including inspection reports and welding logs, provides traceability and verification, necessary for welding projects requiring high reliability and safety.

Challenges in Achieving Full Penetration

Achieving full penetration in welds presents numerous technical challenges, including proper joint preparation, precise heat input control, and effective welder technique. These factors are crucial in ensuring the weld is structurally sound and meets industry standards.

Joint Preparation: Inadequate cleaning or improper beveling can hinder weld penetration, leading to defects such as lack of fusion or incomplete penetration.

Heat Input Control: Excessive or insufficient heat can cause issues like burn-through or insufficient fusion, respectively. Consistent heat management is essential.

Welder Technique: The skill level of the welder plays a significant role. Poor technique can lead to irregular weld beads, porosity, and other defects that compromise weld integrity.

Mastering these challenges is essential for achieving reliable, high-quality full penetration welds.

Best Practices for Welders

Implementing best practices is vital for welders to achieve consistent, high-quality full penetration welds. Key practices include thorough preparation of the welding joint, guaranteeing proper alignment and fit-up to avoid gaps or misalignment.

Preheating the base material, especially for thicker sections, minimizes thermal shock and reduces the risk of cracking. Using the correct electrode or filler material, as specified in the Welding Procedure Specification (WPS), is essential.

Consistent monitoring of welding parameters such as amperage, voltage, and travel speed ensures uniform penetration. Post-weld inspection, including visual and non-destructive testing (NDT) methods, verifies weld integrity.

Maintaining a clean work environment and adhering to safety protocols further enhance the quality of the welds and the safety of the welder.

Conclusion

In the intricate dance of metallurgy, the symbol for full penetration weld serves as the conductor, orchestrating the symphony of material unity. Its precise design elements and rigorous inspection protocols guarantee a seamless fusion, akin to a master artist's brushstrokes merging colors on canvas.

Employed in critical applications, these welds embody both strength and reliability, distinguishing themselves from partial penetration welds. Ultimately, achieving full penetration is a proof of a welder's skill, akin to a maestro's flawless performance.