Schematic Symbol for Flow Meter: Positive Displacement!

You’ll find that the schematic symbol for a flow meter varies depending on the specific type being represented, such as turbine, positive displacement, magnetic, ultrasonic, or Coriolis meters.

Each symbol succinctly embodies the functionality and application of the flow meter it denotes, ensuring clear, concise communication within technical diagrams.

Mastering these symbols allows you to accurately analyze and interpret system layouts, enhancing your ability to diagnose and optimize processes.

Familiarizing yourself with the standard symbols for different flow meter types prepares you for selecting the appropriate device for any given task.

Further exploration will equip you with deeper insights into integrating these symbols effectively in your projects.

Key Takeaways

Understanding Schematic Symbols

Understanding schematic symbols is essential for analyzing and interpreting technical diagrams accurately.

Each symbol serves as a concise representation of an element within a system, allowing you to grasp complex concepts quickly.

You’ll encounter symbols that represent various components, from resistors in electrical circuits to valves in hydraulic systems.

To master this language, you must familiarize yourself with the standard symbols used in your field. This involves recognizing shapes and understanding their meanings within specific contexts.

For instance, a simple circle might denote a measuring point in one diagram, yet signify a connector in another.

By honing your ability to decipher these symbols, you’ll enhance your technical literacy, enabling you to navigate and understand sophisticated diagrams with confidence and precision.

The Basics of Flow Meters

You must first understand the diverse functions of flow meters to grasp their importance in measuring fluid movement accurately.

Exploring the various types of flow meters will reveal how their design and operational principles align with specific measurement needs.

Flow Meter Functions

Flow meters are crucial instruments for measuring the rate of fluid or gas passing through a system.

They provide essential data for managing and optimizing processes, particularly in applications where precise flow rate quantification is vital for operational efficiency and safety.

By monitoring flow rates, anomalies like leaks or blockages can be detected early, thus preventing potential system failures or inefficiencies.

Additionally, flow meters play a pivotal role in ensuring compliance with regulatory standards, especially in industries where accurate fluid transfer measurement is mandated.

Moreover, flow meters enable the accurate billing of resource consumption, a critical aspect in sectors such as utilities and oil & gas.

The data collected by flow meters can also help determine predictive maintenance schedules, optimizing equipment lifespan and reducing downtime. In essence, flow meters are indispensable tools for achieving operational excellence.

Types of Flow Meters

Various types of flow meters exist, each designed to accurately measure the flow of liquids or gases through pipes in diverse industrial environments.

You’ll find mechanical meters, like turbine and positive displacement types, which rely on the physical movement of the fluid to operate.

These are straightforward in their application, making them suitable for a range of viscosities and flow rates.

Non-mechanical flow meters, including magnetic, ultrasonic, and Coriolis types, offer advantages in situations where low maintenance or chemical compatibility is critical.

Magnetic meters excel in measuring conductive fluids with minimal pressure drop. Ultrasonic meters, utilizing sound waves, are adept at handling various fluid types without direct contact.

Finally, Coriolis meters provide highly accurate mass flow measurements, invaluable in precision-dependent processes. Each type serves specific needs, ensuring precise control and monitoring across sectors.

Understanding Measurement Units

Having explored the diverse types of flow meters, it’s important to understand the measurement units they employ to guarantee accurate and consistent flow readings.

Primarily, flow meters measure liquid, gas, or steam flow in units such as liters per minute (L/min), cubic meters per hour (m³/h), gallons per minute (GPM), and standard cubic feet per minute (SCFM).

Each unit provides a specific insight into the flow’s quantity, allowing for precise control and monitoring. When selecting a flow meter, it’s vital to match the unit of measurement to your system’s requirements.

This secures that the data you collect aligns with operational standards, facilitating effective analysis and decision-making.

Understanding these units is fundamental in optimizing process efficiency and achieving the desired outcomes in various applications.

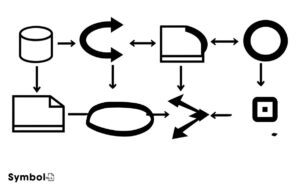

Identifying Flow Meter Symbols

As you progress in understanding flow meters, identifying their schematic symbols becomes essential.

You’ll need to recognize the various types of flow meters, ensuring accuracy in reading these symbols.

Grasping symbol interpretation tips will further enhance your ability to accurately analyze and apply this knowledge in practical scenarios.

Types of Flow Meters

To accurately interpret flow meter schematics, it’s important to familiarize yourself with the different symbols representing various types of flow meters.

Each symbol encapsulates a unique set of characteristics and working principles inherent to the flow meter it represents.

For instance, the turbine flow meter, often symbolized by a fan-like icon within a circle, operates on the principle of fluid flow turning a turbine blade.

Conversely, the electromagnetic flow meter, indicated by a pair of parallel lines within a circle, relies on Faraday’s law of electromagnetic induction to measure flow.

Understanding these symbols isn’t just about recognizing shapes; it’s about appreciating the underlying technology and its application in measuring flow rates accurately.

This knowledge enables you to decode schematics effectively, ensuring precision in design and analysis.

Reading Symbols Correctly

Correctly interpreting flow meter symbols is essential for accurately analyzing fluid dynamics in various engineering applications.

Recognizing these symbols allows you to understand the flow measurement being depicted, which is vital for system design, analysis, and troubleshooting.

When identifying flow meter symbols on schematics, consider the following:

- Look for a symbol that typically represents the flow direction, often indicated by an arrow.

- Identify the specific shape or pictogram that suggests the flow meter type, such as a turbine, orifice, or ultrasonic.

- Note any additional markings or annotations that specify measurement units or range.

- Pay attention to the context within the schematic; placement can hint at the flow meter’s role in the system.

- Understand that variations exist between different schematics; familiarity with standards and conventions in your field is key.

Grasping these elements ensures you’re equipped to accurately interpret and apply the information portrayed by flow meter symbols in engineering documents.

Symbol Interpretation Tips

Identifying flow meter symbols on schematics requires a keen eye for detail and an understanding of specific graphical elements.

To discern these symbols accurately, you’ll need to familiarize yourself with common traits that distinguish them from other components.

Flow meters often depict a basic shape, such as a circle or rectangle, with one or more arrows indicating the flow direction.

Inside, you might find symbols or abbreviations specific to the type of flow meter, such as ‘TM’ for turbine meter or ‘VM’ for vortex meter.

Paying attention to these subtleties is essential. Additionally, look for accompanying labels or notes that provide further specification, ensuring you’re interpreting the symbol within the correct context.

Mastery of these tips will enhance your schematic reading skills significantly.

Varieties of Flow Meters

Understanding the various types of flow meters is essential for selecting the appropriate device for measuring fluid flow in your system.

Depending on your application’s specific requirements, you’ll find that each type offers unique advantages.

Here’s a concise overview:

- Differential Pressure Flow Meters: Ideal for measuring flow rates of liquids, gases, and steam by creating a pressure drop across a flow restriction.

- Positive Displacement Flow Meters: Accurately measure the volume of fluid passing through by capturing it in compartments.

- Turbine Flow Meters: Use the mechanical energy of the fluid to rotate a turbine in the flow stream, suitable for liquids and gases.

- Electromagnetic Flow Meters: Measure flow based on the voltage generated as fluid passes through a magnetic field, great for conductive liquids.

- Ultrasonic Flow Meters: Determine flow rate by analyzing the frequency shift of ultrasonic signals as they traverse the fluid.

Symbol Components Explained

To effectively interpret a flow meter’s schematic symbol, you’ll need to familiarize yourself with its various components. At its core, a flow meter symbol typically includes a base figure—often a circle or a rectangle.

This shape signifies the meter’s body or primary sensing element. Inside or adjacent to this base figure, there may be additional symbols or lines.

These elements represent the flow meter’s sensing mechanism, such as a turbine, paddle, or ultrasonic sensor.

Arrows or directional indicators are also common, illustrating the intended flow direction through the meter.

Understanding these components is essential as they convey essential information about the flow meter’s operation, type, and directional flow requirements, providing a foundation for accurate system analysis and design.

Interpreting Symbol Variations

After familiarizing yourself with the basic components of a flow meter’s schematic symbol, you’ll need to learn how to interpret the variations in these symbols to accurately determine the meter’s functionality and application.

Understanding these variations is essential for selecting the appropriate meter for your specific needs.

Consider these key symbol variations:

- Additional lines indicate the presence of auxiliary equipment or features.

- Differing shapes may signify the flow meter type, such as turbine, ultrasonic, or electromagnetic.

- Symbols within the circle can represent specific measurement techniques or technologies.

- Varied border styles might denote meter accuracy or intended use environment.

- Color coding or shading could provide information on the fluid type or meter material compatibility.

Each variation holds critical information that aids in the precise selection and application of flow meters.

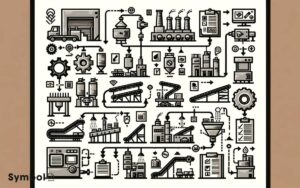

Application in Piping Diagrams

Incorporating flow meter schematic symbols into piping diagrams allows you to accurately map out fluid movement and equipment relationships within systems.

As you explore these diagrams, you’ll find that each symbol’s placement is crucial for understanding how fluids navigate through pipes, valves, and other components.

It’s not just about where the flow meter is positioned; it’s also about grasping the type of flow, whether it’s liquid, gas, or steam, and the direction of movement. This level of detail helps in predicting system behavior under various operating conditions.

Flow Meter Symbol Specifications

Understanding flow meter symbol specifications is essential for accurately interpreting and implementing these markers in your piping diagrams.

When you’re engaging with these symbols, consider the following key specifications:

- Shape: Identifies the flow meter type, where certain shapes denote specific meter technologies.

- Orientation: Indicates the flow direction, important for correct installation and operation.

- Lines: Represents the connections to the process line, showing how the meter integrates into the system.

- Identification Tag: A unique identifier for each meter, allowing for easy reference in documentation.

- Additional Marks: Highlight special features or requirements, such as temperature or pressure compensation.

Reading Complex Schematics

Traversing through the intricacies of complex schematics requires you to recognize and interpret various symbols and their connections accurately.

Each symbol represents a specific component or function within the system, and understanding these is essential for analyzing the overall design.

You’ll encounter symbols for resistors, capacitors, and, pertinent to this discussion, flow meters, among others.

Deciphering the relationship between symbols involves grasping the flow of signals or materials through the system.

This means identifying the inputs and outputs of each component and how they contribute to the system’s operation.

Paying close attention to directional arrows, lines indicating connections, and annotations can provide insights into the schematic’s logic and functionality.

Mastery of reading these diagrams empowers you to troubleshoot, modify, or design complex systems efficiently.

Symbol Integration in Systems

You’ll encounter challenges in interpreting flow meter symbols within complex systems, requiring a keen eye for detail.

Adhering to integration best practices guarantees seamless compatibility with other schematic symbols, enhancing system coherence.

Understanding these principles is essential for accurate schematic analysis and effective communication across engineering teams.

Symbol Interpretation Challenges

Integrating flow meter symbols into system schematics often presents challenges due to their complexity and the necessity for precise interpretation.

You’re moving through a technical landscape where every detail counts, and misinterpretation can lead to significant system errors.

Consider the following hurdles:

- Variations in symbol design across different standards.

- The need for a deep understanding of flow meter types and their specific symbols.

- Difficulty in distinguishing similar symbols for different metering devices.

- The challenge of keeping schematic representations updated with the latest technology.

- Potential confusion when integrating with symbols from other system components.

These challenges demand a meticulous approach to symbol interpretation, ensuring that every schematic accurately reflects the intended system design. It’s essential to address these issues head-on to facilitate seamless integration and operational efficiency.

Integration Best Practices

To guarantee smooth integration, it’s essential to adopt a systematic approach when incorporating flow meter symbols into system schematics.

You’ll need to make sure that each symbol accurately represents the specific type of flow meter being used, considering its unique characteristics and operational parameters.

This involves selecting symbols that clearly convey the function, range, and limitations of the device within the context of the overall system.

Additionally, it’s important to maintain consistent symbol usage throughout the schematic to prevent confusion and misinterpretation.

Proper labeling and annotation are also necessary, providing key details such as the flow meter’s model, capacity, and any critical settings.

Compatibility With Other Symbols

Verifying compatibility among flow meter symbols and other system schematic icons demands a meticulous examination of their design and function parameters.

You’ll want to guarantee seamless integration within your schematics, avoiding potential misinterpretations or errors in system analysis and construction.

To achieve this, consider the following:

- Consistency in Symbol Design: Verify that the flow meter symbol stylistically matches other schematic icons.

- Standardized Sizing: Maintain symbol sizes proportional to ensure readability.

- Functionality Indicators: Include clear, distinct features that signify the flow meter’s specific function.

- Alignment with Industry Standards: Comply with widely recognized standards for schematic drawings.

- Color Coding: Use color strategically to differentiate between various system components.

Practical Tips for Engineers

Mastering the interpretation of flow meter schematic symbols can greatly enhance your engineering projects’ efficiency and accuracy. Initially, make sure you’re familiar with the standard symbols.

Each variation represents a different type of flow meter, such as turbine, ultrasonic, or electromagnetic.

Understanding these differences is essential for selecting the appropriate meter for your specific application. Next, pay attention to the context in which these symbols are used within the schematic.

The placement can offer insights into the flow direction, required accuracy, and potential integration with other system components.

Future Trends in Flow Measurement

How will emerging technologies reshape the landscape of flow measurement in the coming years? You’re about to see a significant transformation driven by innovation, optimizing the precision and efficiency of flow meters.

Here’s what to anticipate:

- Integration of IoT: Enhanced connectivity for real-time data monitoring and analysis.

- Advanced Materials: Development of more durable, corrosion-resistant materials for longer lifespan.

- Miniaturization: Smaller, more compact devices without compromising accuracy.

- Artificial Intelligence and Machine Learning: For predictive maintenance and improved accuracy through adaptive algorithms.

- Non-invasive Techniques: Increased adoption of methods that don’t require pipe modification, reducing installation and maintenance costs.

These trends signify a shift towards smarter, more efficient flow measurement solutions, offering you unprecedented levels of control and insight into your systems.

Conclusion

In a world dominated by the relentless flow of everything from water to data, mastering the mystical symbols of flow meters isn’t just a skill it’s akin to wielding magic.

By grasping the intricate symbols and their components, you’re not just reading schematics; you’re deciphering the very language of the cosmos.

Remember, in the domain of engineering, these symbols are your sword and shield.

Embrace them, and you’ll navigate the intricate labyrinths of systems like a legendary hero, ready to tackle the futuristic frontiers of flow measurement with unparalleled precision and analytical prowess.