How to Identify Choke Off and On Symbols on Small Engines

Understanding the choke on and off symbols is vital for ensuring engine efficiency and performance. The choke on symbol is typically represented by a closed or filled circle, indicating restricted airflow to enrich the fuel mixture, aiding cold engine starts.

The choke off symbol signifies normal airflow, essential for fuel efficiency and engine health. Familiarity with these symbols enables best fuel-air mixture adjustments, preventing issues like stalling or excessive fuel consumption.

Accurate use of choke controls can notably impact engine longevity and performance, from small engines to modern automobiles. To master this aspect of engine management, there are more technical insights worth exploring.

Key Takeaways

- The choke on symbol is represented by a closed or filled circle, indicating restricted airflow.

- The choke off symbol signifies the disengaged choke mechanism, allowing normal airflow.

- The choke on symbol is used to enrich the fuel mixture for cold engine starts.

- The choke off symbol ensures fuel efficiency and normal engine operation after warm-up.

- Proper use of choke symbols helps optimize engine performance and longevity.

What Is a Choke?

A choke is a mechanical or electronic device used to regulate the air-fuel mixture in an internal combustion engine during startup. It achieves this by temporarily restricting airflow into the carburetor or throttle body, enriching the fuel mixture, which is essential for cold engine conditions.

The choke can be manually operated by the driver or automatically controlled by a thermostat or electronic system. In manual systems, the driver adjusts the choke via a lever or cable. Automatic chokes use temperature-sensitive elements to adjust the air intake.

Proper functioning of the choke ensures smooth engine starts, reduces wear, and prevents stalling. Understanding the choke's role is vital for diagnosing startup issues and maintaining engine performance.

Choke On Symbol

The 'Choke On' symbol is typically represented by a closed or filled circle, indicating the restriction of airflow to enrich the fuel mixture.

Proper placement of this symbol on machinery or equipment is essential for user clarity and operational safety.

The symbol must be prominently displayed near the choke control mechanism, ensuring immediate user recognition and correct usage.

Identifying Choke On

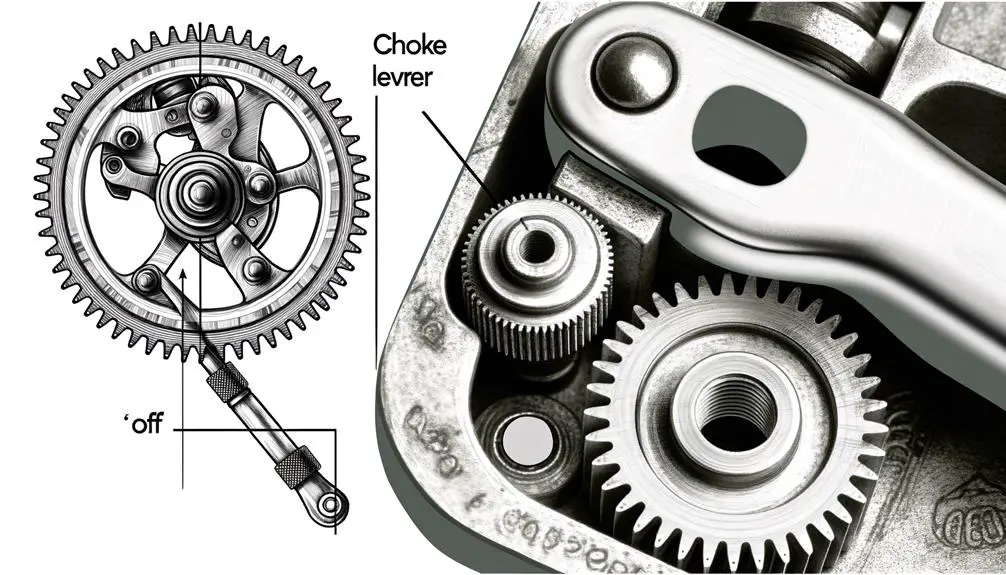

To correctly identify the 'Choke On' position, locate the symbol typically represented by a fully shaded circle or a solid line on the control lever. This symbol is a universal indicator of the choke being engaged, restricting air flow to enrich the fuel mixture for starting a cold engine.

Precise identification is essential as the choke's function is crucial to optimizing engine startup performance. When the choke is on, the engine receives less air, facilitating a richer fuel mixture necessary for ignition under cold conditions.

Be sure to visually confirm this symbol on the control lever or nearby interface, as manufacturers consistently use these standardized markings to denote the engaged choke state. Accurate identification prevents operational inefficiencies and starting issues.

Symbol Placement Guide

Symbol placement for the 'Choke On' indicator is typically found on the control lever or adjacent panel, guaranteeing clear visibility and quick identification for the operator. This strategic positioning allows for intuitive access and operation, especially under varying environmental conditions.

The symbol should be prominently displayed, often using contrasting colors to enhance recognition. In most designs, the 'Choke On' indicator is accompanied by a corresponding 'Choke Off' symbol, facilitating smooth switch between states.

Accurate placement reduces operational errors, thereby enhancing machinery performance and user safety. Proper alignment with ergonomic principles ensures that operators can engage the choke mechanism without undue strain, promoting efficient and effective equipment use.

Choke Off Symbol

The Choke Off Symbol serves as a critical indicator to signify when the choke mechanism is disengaged, ensuring proper engine functionality.

Placement guidelines for this symbol necessitate high visibility and intuitive positioning to avoid operator confusion.

Adhering to standardized symbol designs enhances user comprehension and compliance with safety regulations.

Choke Off Indicator

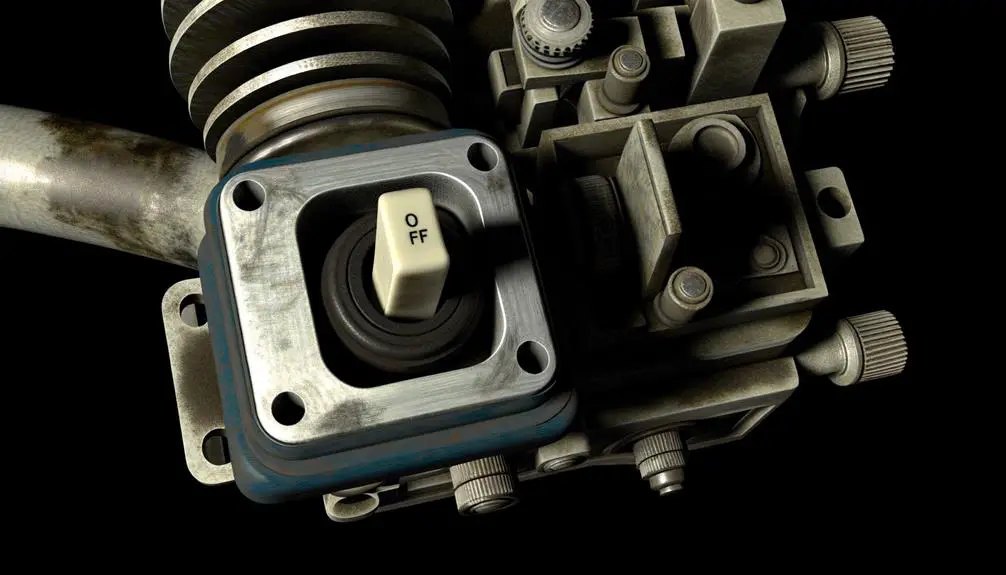

A choke off indicator, often represented by a specific symbol on machinery or vehicles, signifies the position where the choke is fully disengaged, allowing for normal airflow to the engine.

This is essential for best engine performance, especially once the engine has warmed up. The symbol typically resembles a horizontal line or an open circle, indicating that the choke valve is in the open position.

Proper identification and interpretation of this symbol guarantee that the engine operates efficiently, reducing the risk of excessive fuel consumption or engine flooding.

Understanding this indicator is vital for maintaining engine health and achieving peak fuel efficiency, thereby prolonging the lifespan of the machinery or vehicle.

Symbol Placement Guidelines

Proper positioning of the choke off symbol is crucial for enabling operators to easily identify and interpret the indicator during machinery or vehicle operation. The symbol should be strategically placed for best visibility and accessibility. Below are the guidelines for effective symbol placement:

| Location | Visibility | Accessibility |

|---|---|---|

| Control Panel | High | Easy Reach |

| Dashboard | Medium | Moderate Reach |

| Near Throttle | High | Easy Reach |

| Instruction Manual | Low | Reference Only |

Placing on the control panel or near the throttle ensures the choke off symbol is within the operator's direct line of sight. However, positioning on the dashboard may require additional attention to guarantee it is not obscured by other indicators. Always prioritize user ergonomics and safety.

Importance of the Choke

Understanding the critical role of the choke in internal combustion engines is crucial for optimizing performance and guaranteeing reliable operation. The choke regulates the air-fuel mixture, particularly during cold starts, and its proper function directly impacts engine efficiency.

Key aspects of the choke's importance include:

- Cold Start Assistance: Enriches the fuel mixture, facilitating engine start in low temperatures.

- Emissions Control: Reduces harmful emissions by guaranteeing complete fuel combustion.

- Fuel Efficiency: Optimizes fuel consumption by adjusting the air-fuel ratio.

- Engine Longevity: Prevents engine wear by providing the correct fuel mixture.

- Operational Stability: Ensures smooth engine operation across varying conditions.

These factors underscore the choke's crucial role in maintaining engine health and performance.

Identifying Choke Symbols

Recognizing and interpreting choke symbols are vital skills for anyone working with internal combustion engines, as these symbols provide critical information regarding the choke's status and operation. Choke symbols typically include an open circle or a partially shaded circle to indicate the 'choke off' position, signifying unrestricted airflow to the carburetor.

Conversely, the 'choke on' position is often represented by a filled or fully shaded circle, indicating restricted airflow to enrich the fuel mixture. Some systems may use a butterfly valve icon, either open or closed, to depict similar states. Understanding these symbols ensures precise control over engine starting procedures and peak performance, minimizing potential issues related to incorrect choke settings.

When to Use Choke On

The choke should be activated during a cold engine start to enrich the fuel-air mixture, facilitating easier ignition. This adjustment is critical in ensuring best combustion when the engine temperature is low.

Additionally, maintaining the choke on during initial engine warm-up helps stabilize engine performance and prevents stalling.

Cold Engine Start

In cold weather conditions, engaging the choke mechanism is vital to facilitate the initial combustion process in an internal combustion engine. This procedure guarantees that the engine receives a richer fuel mixture, which is necessary for combustion when temperatures are low.

Key steps to follow for a successful cold engine start include:

- Engage the choke: Activate the choke to restrict airflow and enrich the fuel mixture.

- Turn the ignition key: Start the engine while the choke is engaged.

- Warm up the engine: Allow the engine to run for a few minutes to reach operating temperature.

- Gradually disengage the choke: Slowly open the choke as the engine warms up.

- Monitor engine performance: Confirm the engine runs smoothly before fully disengaging the choke.

This method optimizes starting efficiency in cold conditions.

Fuel-Air Mixture Control

Utilizing the choke to control the fuel-air mixture is crucial during specific engine operating conditions to guarantee peak combustion efficiency. When the choke is engaged, it restricts airflow into the carburetor, enriching the fuel mixture.

This is particularly crucial during cold starts, as a richer mixture compensates for low vaporization rates of fuel in cold conditions, facilitating ignition. Additionally, the choke should be employed when operating in environments with low ambient temperatures or high humidity, where the fuel may not adequately atomize.

Proper use of the choke guarantees the engine receives an ideal air-fuel ratio, preventing rough idling, stalling, or inefficient combustion. Effective choke management is therefore essential for maintaining engine performance and longevity.

Initial Engine Warm-Up

During the initial engine warm-up phase, engaging the choke is essential to maintain a richer fuel mixture that supports smooth ignition and stable idling. This phase is particularly important for engines operating in colder environments or after prolonged inactivity. The choke restricts air intake, enriching the fuel mixture, and facilitating combustion.

Key indicators for using the choke during warm-up include:

- Cold ambient temperatures: Guarantees the engine receives adequate fuel.

- First start of the day: Compensates for lower engine temperature.

- Rough idling: Stabilizes engine speed and performance.

- Delayed ignition: Aids in quicker startup and efficiency.

- Manual choke systems: Requires user intervention for best fuel mixture.

Understanding these factors ensures the engine warms up effectively, preventing mechanical stress and promoting longevity.

When to Use Choke Off

Properly identifying when to use choke off is vital for ensuring best engine performance and preventing potential damage. The choke should be turned off once the engine has warmed up adequately and is able to run smoothly without additional fuel enrichment. This typically occurs after a few minutes of operation, depending on ambient temperature and engine specifics.

Monitoring engine behavior is pivotal; if the engine starts to sputter or run inefficiently, the choke should be re-engaged momentarily. Turning the choke off too early can lead to stalling and poor performance, while leaving it on too long can cause excessive fuel consumption and carbon buildup.

Ensuring the correct timing for choke disengagement optimizes fuel efficiency and prolongs engine life.

Common Choke Locations

Choke controls are commonly located on the carburetor, integrated into the throttle assembly, or positioned on the dashboard for easy access. The precise location can vary based on the design and type of the equipment. Users should familiarize themselves with the choke's position to guarantee efficient operation.

Here are common choke locations:

- Carburetor: Often found directly on the carburetor for manual adjustment.

- Throttle Assembly: Integrated into the throttle lever, combining both throttle and choke functions.

- Dashboard: Positioned on the dashboard for automobiles, allowing easy access.

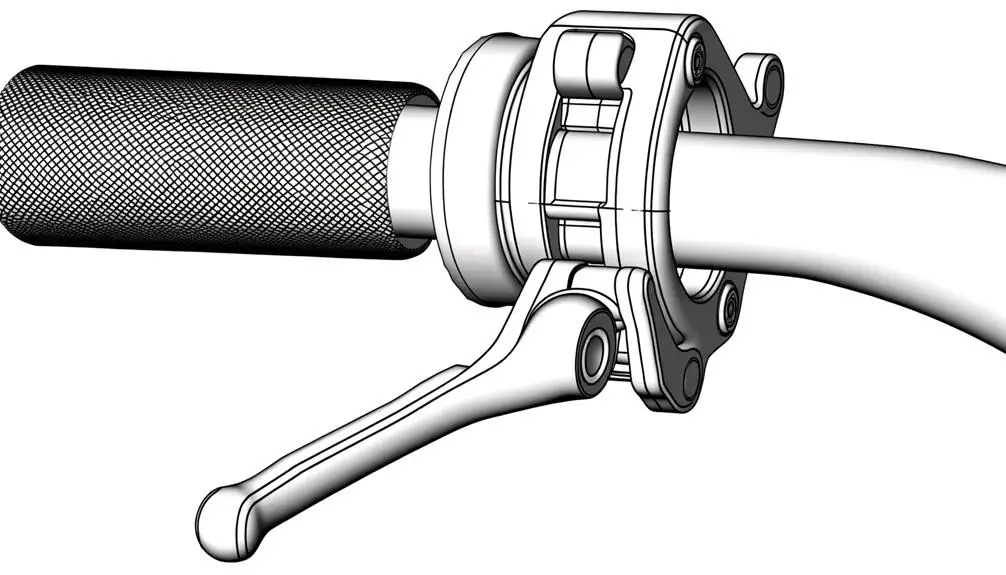

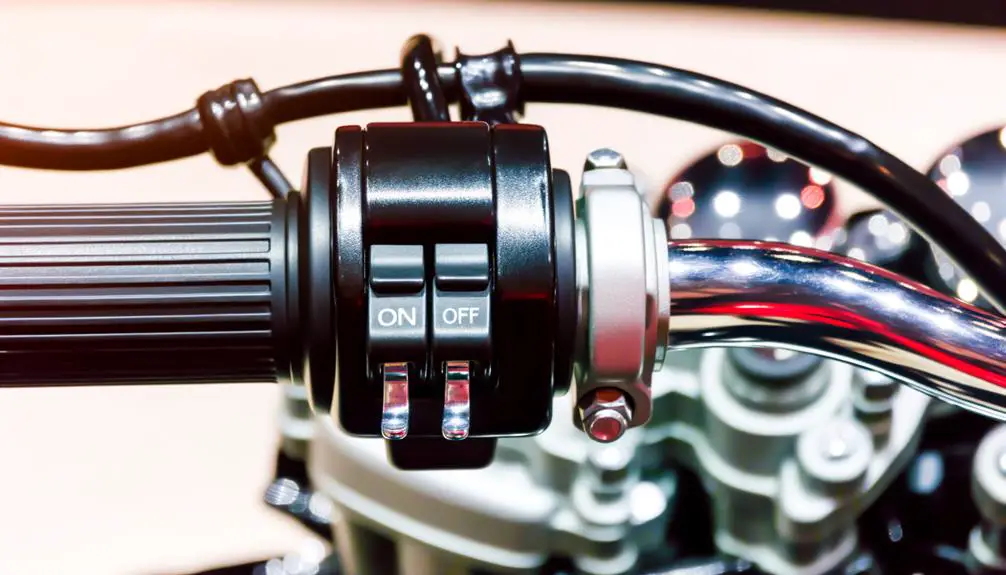

- Handlebar: Common in motorcycles and ATVs for quick reach.

- Side Panel: Found on power equipment like lawnmowers, ensuring user convenience.

Understanding these locations enhances operational efficiency and guarantees proper engine management.

Choke in Different Machines

Recognizing the specific choke mechanisms in various machines is critical for ensuring peak performance and ease of operation. In small engines, such as lawn mowers and chainsaws, manual choke levers are often utilized. These levers adjust the air-fuel mixture, facilitating cold starts.

Motorcycles typically feature a handlebar-mounted choke lever for quick adjustments on the fly. In contrast, many modern automobiles integrate automatic choke systems controlled by the engine control unit (ECU), optimizing the air-fuel ratio without user intervention.

Generators often employ a pull-choke mechanism, which must be manually engaged and disengaged during startup. Each type of machine employs a choke system tailored to its operational requirements, highlighting the importance of understanding these variations for efficient usage and maintenance.

Troubleshooting Choke Issues

Diagnosing choke issues requires a methodical approach, starting with verifying the correct positioning of the choke lever or control mechanism. Confirming the choke is neither stuck nor partially engaged is essential.

Follow these steps for effective troubleshooting:

- Inspect the choke cable: Look for signs of wear, fraying, or misalignment.

- Check for obstructions: Make sure no debris or dirt is blocking the choke mechanism.

- Test the choke valve: Verify it opens and closes smoothly without resistance.

- Examine fuel flow: Confirm that the fuel supply is consistent and unimpeded.

- Assess engine performance: Note any irregularities in engine start-up or idle behavior.

These precise checks can help isolate and resolve choke-related problems efficiently, ensuring peak engine function.

Tips for Proper Choke Use

For best engine performance, it is important to understand the correct timing and manner in which to engage and disengage the choke.

Initially, engage the choke fully before starting a cold engine to secure an ideal air-fuel mixture. Once the engine starts, gradually open the choke as it warms, monitoring for smooth operation. Avoid keeping the choke engaged longer than necessary, as this can lead to excessive fuel consumption and potential engine flooding.

In contrast, disengage the choke promptly under warm conditions to prevent overly rich mixtures. Regularly inspect choke linkage and cables for proper function, making sure they move freely without binding.

Mastery of these techniques will contribute significantly to engine longevity and performance reliability.

Conclusion

Understanding the symbols for choke on and off is essential for the proper operation of various machines.

For example, in a case where a snowblower fails to start in cold weather, correctly identifying and using the choke can mean the difference between a functioning machine and hours of troubleshooting.

Mastery of choke symbols guarantees peak performance and longevity of equipment, emphasizing the importance of accurate identification and application in mechanical operations.